Livarna Gorica d.o.o., Nova Gorica

Performance and Precision Castings

The foundry LIGO (Livarna Gorica d.o.o.), a company of the ZÜRN Group, is located in Nova Gorica, Slovenia, near the Italian border. More than 25 years of experience in the production of complex, individual grey cast iron components make LIGO a competent and reliable partner. With an export quota of over 90%, the convenient location is an important location advantage. With an annual capacity of over 10,000 tonnes of demanding, mostly thin-walled and core-intensive castings, a team of over 90 employees ensures high-quality solutions.

Your reliable partner for challenging solutions

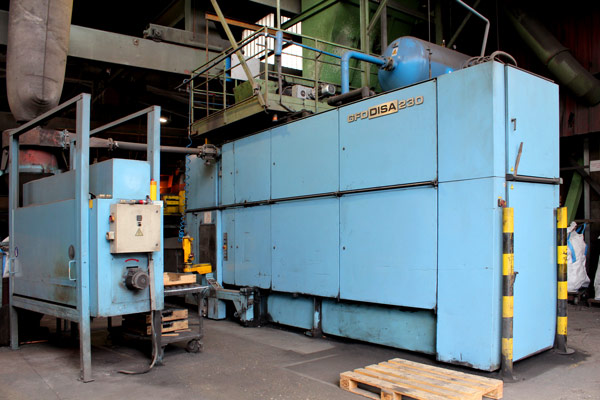

LIGO is a foundry for high-quality, individual solutions. With modern production and machining systems such as a GF DISAMATIC 230 A, high quantities can be produced with fast throughput times. The particular strength and core competence of the LIGO foundry lies in the production of thin-walled, complex grey cast iron components up to a wall thickness of approx. 2 mm. The affiliation to the internationally active ZÜRN Group also enables cost-effective and effective options for further processing, finishing and assembly of additional components on the casting, such as coating or assembly with other materials.

Quality is our supreme priority

LIGO offers reliable casting production at the highest quality level and reliable customer service with highly flexible logistics services Innovative quality management with continuous process optimisation based on ISO 9001:2000 creates exemplary transparency and offers a high level of quality reliability Long-term customer satisfaction is LIGO’s top priority. This establishes the foundry as a competent and high-performance partner that develops complex solutions for cast components together with its customers, thus ensuring market attractiveness and shaping the future.

Efficient investments in the future

LIGO is technically state-of-the-art and is able to react quickly to new market requirements. LIGO uses the most modern and efficient systems and machines for high-quality cast production and cast machining These are constantly optimised and further expanded, also from an ecological point of view, e.g. by installing the most modern filter and cleaning systems. Environmental protection and sustainable growth are among the responsible challenges for securing performance and a successful future.